Hi there! How is it going? We hope all is going well with you.

Alchemists already knew that everything in nature is made of these 4 basic elements: Fire, Earth, Air, and Water. The fifth one, the Aether, is still to be studied and comprehended as it is related to the unseen, the “spiritual” realm. However, perhaps we are very close to discovering more about it.

Brazilian researchers just recently got close to identifying rare human genes related to the development of mediumship, or the ability to communicate with the unseen, the ‘beyond’. Learn more about this intriguing research on: Candidate Genes Related to Spiritual Mediumship: A Whole Exome Sequencing Analysis of Highly Gifted Mediums

Considering that most common people do not have those abilities developed, but they are still made of those basic natural elements, it is paramount that they would be extremely needed in our healing processes, either physically or mentally, as many contemporary scientific studies show.

In the face of global health crises like the COVID-19 pandemic, the need for rapidly deployable, high-quality healthcare facilities has become paramount. Addressing this critical demand, Farrow Partners, in collaboration with Nucap Industries, introduced the Solace© Rapid Assembly system—an innovative approach to constructing high-performance inpatient bed solutions that are faster, smarter, safer, more adaptable, and, importantly, healthier.

The Solace© Rapid Assembly system also allows the presence of those natural elements in our healing environments, mainly through natural sun light (or, the fire element). Perhaps, in the future we will have healthcare facilities that allow other natural elements inside whenever appropriate. That would be a big win for our health care system, highly focused on machines, cost and functionality.

The Genesis of Solace© Rapid Assembly

The term “Solace” originates from the Latin verb “solari,” meaning to comfort, calm, and soothe one’s grief. This concept underscores the project’s mission: to create healthcare environments that provide solace to both patients and medical staff during challenging times. Recognizing the acute need for rapid-response solutions that do not compromise on quality, the Solace team set out to design inpatient bed environments that support the well-being and performance of healthcare workers, particularly doctors and nurses operating under immense stress.

View from within staff area of temporary Solace ward with natural lighting. Source: https://www.canadianarchitect.com/farrow-partners-develops-clt-blocks-for-quick-assembly-icu-wards/

Innovative Building Blocks: Grip Timber Cross-Laminated Blocks (GTCLB)

At the heart of the Solace© Rapid Assembly system lies the Grip Timber Cross-Laminated Block (GTCLB). These blocks are crafted from layers of cross-laminated timber—specifically, wood offcuts from shipping skids—bonded together using Nucap’s “metal Velcro” technology. This adhesive-free method involves thin metal strips that allow the wooden layers to interlock securely, resulting in a robust and lightweight building material. The GTCLB measures approximately 25 centimeters in length and features internal cavities, facilitating the integration of mechanical and electrical conduits. The precision in their design ensures that these blocks can be rapidly assembled and disassembled without the need for specialized labor, akin to a large-scale Lego system.

Cross laminate blocks are used on building and Floor Systems. Source: https://www.ezblocks.ca/the-hospital-of-today-and-tomorrow-is-rapidly-deployable/

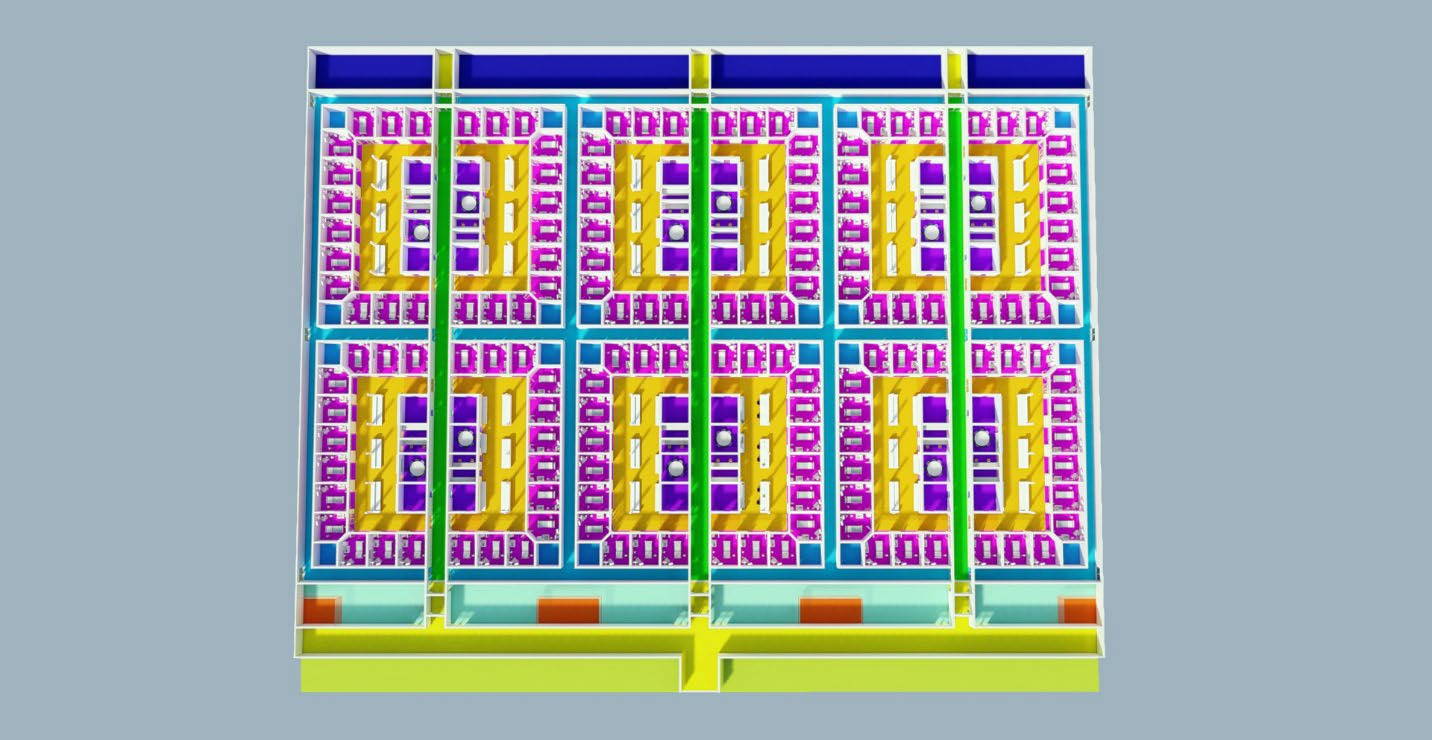

Designing for Health: The 12-Bed ICU Module

The Solace© system’s foundational unit is a 12-bed Intensive Care Unit (ICU) ward, measuring 15 by 30 meters. Patient rooms are arranged along three walls, each equipped with small windows on partition walls to enable nurses to monitor adjacent units efficiently. The central area serves as a medical team zone, while the fourth wall houses staff support facilities. A distinctive feature of this design is the elevated ceiling at the center, forming a lantern-like structure with a four-sided clerestory window. This architectural choice ensures the infusion of natural light, benefiting both patients and medical staff by aligning with circadian rhythms and enhancing overall well-being.

The 12-bed ICU module Floor Plan. Source: https://www.daniels.utoronto.ca/news/wed-may-6-2020-12am/daniels-faculty-alumnus-tye-farrow-designs-new-type-quick-build-temporary

Adaptability and Scalability

One of the standout features of the Solace© Rapid Assembly system is its scalability. The 12-bed ICU modules can be combined to create larger units—24, 36, 48 beds, and beyond—tailored to the specific needs of healthcare facilities. This flexibility ensures that hospitals can rapidly expand their capacity in response to surges in patient numbers without compromising on the quality of care or the working conditions of medical staff.

The 12-bed ICU module can be replicated to fit different scales such as a 12-unit ward. Source: https://www.canadianarchitect.com/farrow-partners-develops-clt-blocks-for-quick-assembly-icu-wards/

Addressing the Challenges of Temporary Healthcare Facilities

Traditional temporary healthcare solutions, such as tent hospitals in convention centers or repurposed shipping containers, often fall short in providing adequate space, natural light, and a conducive healing environment. These setups can lead to increased stress and reduced efficiency among medical staff. In contrast, the Solace© system emphasizes enriched environments that promote health. By incorporating elements like natural light, spacious layouts, and intuitive design, the system creates spaces that not only facilitate healing for patients but also support the mental and physical well-being of healthcare providers.

Section through staff care centre and inpatient room. Source: https://www.daniels.utoronto.ca/news/wed-may-6-2020-12am/daniels-faculty-alumnus-tye-farrow-designs-new-type-quick-build-temporary

Beyond the Pandemic: Future Applications

While the Solace© Rapid Assembly system was conceived in response to the COVID-19 pandemic, its applications extend far beyond. The innovative GTCLB technology holds promise for addressing various architectural challenges, including affordable housing and long-term care facilities. For instance, in northern communities with access to sawmills, residents could produce their own building blocks, empowering them to construct homes and community structures efficiently. This adaptability showcases the system’s potential to revolutionize construction practices in diverse settings.

A Paradigm Shift in Healthcare Architecture

The Solace© Rapid Assembly system represents a significant advancement in healthcare architecture. By harmonizing rapid deployability with high-quality, health-promoting environments, Farrow Partners and Nucap Industries have set a new standard for emergency healthcare infrastructure. This approach not only addresses the immediate needs posed by health crises but also paves the way for more resilient and adaptable healthcare systems in the future.

In conclusion, the Solace© Rapid Assembly system exemplifies how innovative design and engineering can come together to create healthcare environments that are not only functional and rapidly deployable but also nurturing and supportive for both patients and healthcare providers. As we navigate current and future health challenges, such forward-thinking solutions will be instrumental in building resilient and compassionate healthcare infrastructures.

In case you are interested in healthcare facilities that embrace nature, please don’t miss our previous great Blog posts about the Bendigo Hospital, in Australia, and the Khoo Teck Puat Hospital, in Singapore.

Cover Image Source:

Important Sources:

https://www.ezblocks.ca/the-hospital-of-today-and-tomorrow-is-rapidly-deployable/

Farrow Partners develops Grip Timber CLT blocks for quick-assembly ICU wards